Phoenix Industries at a Glance

We are one of the leading Manufacturers, Suppliers of Precision Machined Bar Turned Components and Assemblies. Contact us for Sealant Injection Grease Fittings, Instrumentation Valves & Accessories, Heat Exchangers, General Engineering Components in Maharashtra, India."

Phoenix Industries is an ISO 9001:2015 certified company that has been designing and manufacturing shell and tube type heat exchangers, Oil Cooler Heat Exchanger, Sealant Injection Grease Fittings, High Pressure Instrumentation Valves, Heat Exchangers, Precision Machined Components and Sub-assemblies for Oil and Gas Industries, Chemical Industries, Power Industries, & Marine Applications, Foundries for the last 22+ years.

Our founder Mr. Sachin Kulkarni is an epitome of experience and motivates his robust team to perform above expectations. The company is being managed by promoters who have the required technical and financial expertise and they work in synchronization with a dedicated team of engineers and technocrats to excel in everything they do.

We believe in ‘KAIZEN’ a Japanese principle of quality management which enables us for continuous improvement of our products and services, and hence maintaining ‘TOTAL QUALITY MANAGEMENT (TQM)’. We assure you the ‘Best’ quality product with ‘excellent’ services using precision machines and latest technology at most competitive prices.

Our Core Ideology

Mission

We manufacture precision machined bar turned components and assemblies for high pressure application industries which deals with all types of liquids and gases, critical machining applications & heat exchanger industries with the help of total involvement of our team, process management, highly technical expertise in development of new products , capability of machining and supply in varied materials Grades.

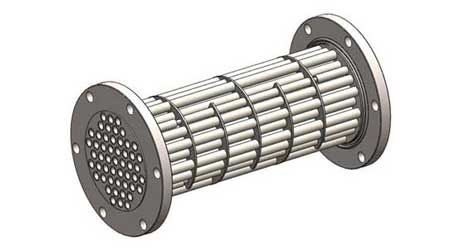

Why to choose Phoenix for Heat Exchangers?

Compact design to save space which makes installation easier.

Premium quality components used in manufacturing.

In house design facility equipped with latest software.

Dedicated welding facilities with certifications to establish manufacturing process for any new material.

Expert team to provide accurate thermal calculations.

Thank you for considering us!

Contact us forShell & tube heat exchangers, Oil cooler heat exchangers in India, USA, UAE, Canada & Russia.

Product Features

- Flexibility of heat exchanger to be designed according to customer requirements, drawings and technical requirements.

- Flexibility in manufacturing and material requirement with various configurations.

- In house design facility equipped with required software and thermal design requirements.

- Strictly adherence to Standards established for Shell and Tube Heat Exchangers.

- Provision for Sacrificial Zinc Anode for Rust Susceptible configurations to prevent decay and corrosion for cost saving configurations.

- Interchangeability of available components.

Technical specifications of our Heat Exchanger

- Design Code: TEMA, ASME SEC VIII, BS-5500, HEI, API

- Flexibility in manufacturing and material requirement with various configurations.

- Type: Fixed Tubes

- Shell diameter: 60 mm to 200 mm

- Tube length: 152 mm to 750 mm

- Tubes: Plain

- M.O.C. Tube: Carbon Steel, Stainless Steel, Copper, Adm. Brass, Aluminum, Bronze, Duplex, Cupro-Nickle, Titanium

- Shell: Carbon Steel, Stainless Steel, Copper, Brass, Aluminum,

Overall Dimensions

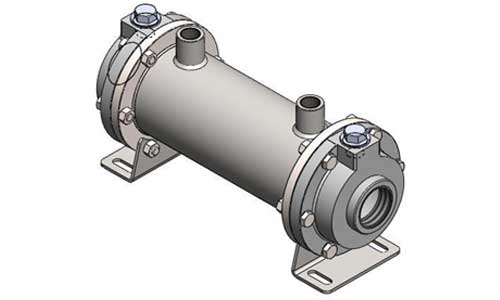

The image above is representative of the Oil Cooler Heat exchanger range from PI-02 to PI-55

| Type | Flow Rate Water/Oil (LPM) |

Dim. A (mm) |

Dim. B (mm) |

Dim. C (mm) |

Weight (kg.) |

|---|---|---|---|---|---|

| PI-02 | 40-60 | 230 | 80 | 60.3 | 4.5 |

| PI-04 | 40-60 | 314 | 150 | 76 | 7.2 |

| PI-07 | 40-60 | 290 | 126 | 89 | 8.9 |

| PI-13 | 40-60 | 314 | 150 | 89 | 9.1 |

| PI-25 | 40-60 | 404 | 236 | 89 | 11 |

| PI-55 | 40-60 | 604 | 414 | 141 | 27.5 |